Melotte submersibles

In their manufacturing plant in Maastricht, Melotte produces an extensive range of submersible pump units (standard ranging from 4” up to and including 12”) and submersible motors with an impeccable reputation. Melotte is able to select and manufacture an adequate submersible pump unit for almost any application. Each Melotte submersible unit is manufactured according the most strict quality standards. In between manufacture many quality assays take place and at the end of the manufacturing process, each Melotte submersible pump unit is submitted to a 100% endurance test.

Melotte in house manufactures Melotte submersible pump units (for some perhaps better known as SUMO Melotte submersible pump units) ranging from 4” up to 12”, which piece by piece are very well known for their high pump efficiencies. These submersible pumps are built stage by stage and are very easy to maintain. Melotte submersible pumps normally are provided with integrated non return valves provided with a valve lining. Flanged or BSP threaded connection can be chosen, for connection to the rising main, in consultation with Melotte if required.

Melotte manufactures 6”, 8” and 10” Melotte submersible motors which are also famous for their reliability and the high motor efficiencies. The “in house” wound stators are assembled with the Melotte produced rotors, provided with copper rotor bars.

The motor bearings belong to the most robust in the market and distinguish themselves by a large standard work-range when frequency controlled. Further Melotte Pumptechnology also is a dealer for the Franklin submersible motors.

MPT-Injectionvalves

Since 2001 Melotte manufactures completely self-designed MPT injection valves and these injection valves momentarily are successfully incorporated in many Aquifer Thermal Energy Storage (ATES) projects for the in these systems required pressure maintenance. Together with the Melotte submersible pump units, these injection valves form a robust and reliable entity. The control of these MPT injection valves takes place by means of separately supplied MPT pilot systems.

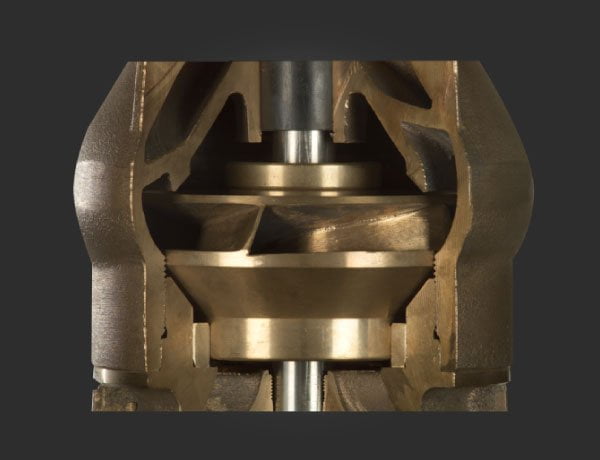

Melotte impeller / pump bowl

Melotte submersible pump units are known for their highest possible pump efficiencies, resulting in the lowest exploitation costs for the customer. Melotte has a large variety of hydraulics in house due to which always the optimal combination between impeller and pump bowl can be selected with the aim to realize your duty point and/or duty area with maximum efficiencies. For this reason, the impellers are turned down exactly to size and the impeller vanes are polished additionally. Melotte in general is capable to adequately approximate any required duty point and/or duty area. Furthermore each pump bowl has its own, easy to replace, bronze neck ring to simplify any possible maintenance.